The NSW Resources Regulator has published an investigation report into a collision between an excavator and a dozer at Maules Creek Mine on 26 May 2021.

According to the report, a dozer was located in front of, and facing towards, the excavator as it was loading a truck. When the excavator finished loading the truck, the dozer driver made a radio call (positive communication or ‘pos-com’) to the excavator operator requesting that he be permitted to move the dozer from the front to the rear of the excavator.

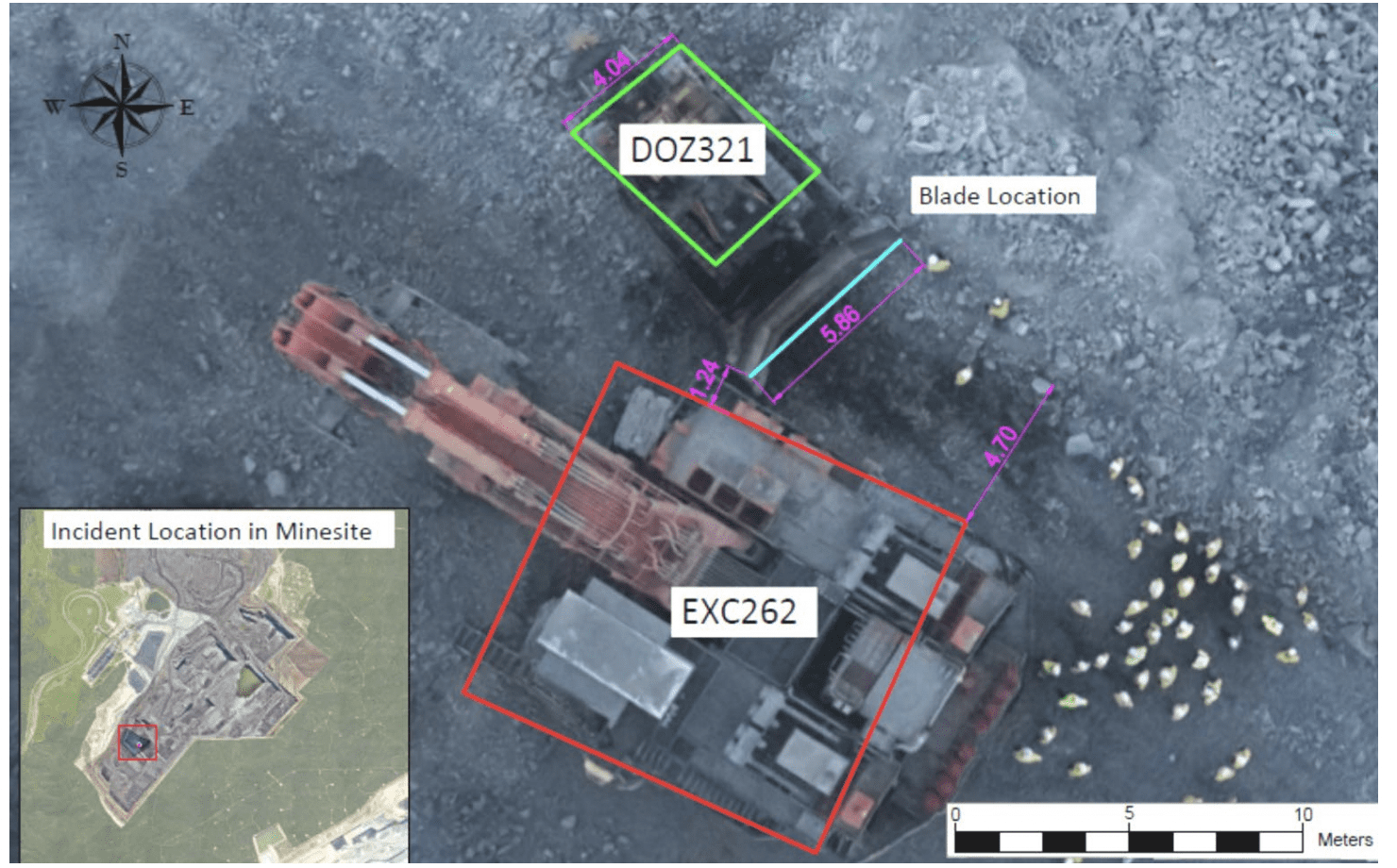

There was a narrow gap on the offside of the excavator and the edge of a bunded low wall where the dozer could pass. The gap was about one metre narrower than the width of the dozer blade.

Incident | Dozer connects with bucket

The excavator operator followed the documented mine procedure by verbally confirming (pos-com) the dozer operator’s request and placing the excavator bucket on the ground. The dozer was visible to the excavator operator through the front window at that time (daylight and dry weather conditions).

The dozer initially moved forward and then reversed backwards and stopped. The excavator operator then slewed the alignment of the excavator parallel with the edge so that the dozer could continue through the off-side swing radius. The dozer then moved forward and out of visual sight of the excavator operator. Whilst the dozer was passing through the off-side swing radius and approaching the counterweight, the excavator operator lifted the bucket and slewed the excavator to present the bucket for the next truck.

The dozer driver saw the rear of the excavator begin to slew and immediately reversed the dozer. The speed of the slewing excavator was faster than the speed the dozer could reverse. The counterweight passed over the dozer blade and struck the cabin structure of the dozer. The dozer operator was wearing a seatbelt and could only move his arm and legs to prevent being crushed by the cabin structure. The crushed cabin jammed the door closed and required the dozer operator to kick out a side window to escape the cabin.

The preliminary investigation identified that the following human and organisational factors contributed to the incident:

- Mining sequence altered: The excavator had excavated a trench across the top of the ramp which was different to the planned sequence of works and, as a result, the path available to the dozer to pass by the excavator was narrowed due to the location of the trench and excavator. The path was 4.7 metres wide relative to the dozer blade width of 5.9 metres (see Figure 2).

- The experienced and trained excavator operator did not comply with the mine’s procedure: The excavator operator became distracted with the mining task whilst the dozer was passing in close proximity to the excavator. As a result, he did not comply with the mine’s procedure and lifted the bucket and slewed the excavator before receiving the second pos-com message from the dozer operator that the dozer was leaving the work area.

- Cues leading to the incorrect assumption made by the excavator operator: The excavator operator incorrectly assumed that the dozer had passed through the swing radius of the excavator and had moved out of the area because of several cues confirming his assumption. The excavator operator said that his decision to re-start the excavator was based on:

- He could not see a dozer in the display screens because he had not selected the offside forward facing camera and he assumed the dozer had left the area.

- It was not an unusual occurrence that he didn’t receive a second pos-com message because some dozer operators did not always give a second pos-com message when moving away from the excavator swing radius or leaving the area.

- The next truck to be loaded was parked with the tray facing the excavator and positioned ready to reverse in to be loaded. He said seeing the tray in the mirror was a visual cue that confirmed his assumption that the dozer had left the area. The mine’s procedure required that when a dozer was working within the swing radius all queuing trucks must be facing with the truck’s cabin facing towards the excavator. He then lifted the bucket and slewed the excavator to present the bucket into the loading position.

- Video cameras not effectively utilised to assist operator awareness: The excavator is fitted with operator awareness devices (four video cameras outside the excavator and two split display screens inside the cabin). It is unclear which cameras were showing on the display screens at the time of the incident. The mine’s procedure does not require the excavator operator to view the off-side cameras when a dozer is passing the off-side of the excavator.

- Diminished situational awareness by the excavator operator of the dozer location: The excavator operator said at the time the dozer was passing the excavator he was thinking about the altered mining sequence. The excavators dig sequence had been altered earlier in the shift due to coal seam horizon variations to create a flat floor horizon. The excavator operator’s attention to the next dig sequence diminished his situational awareness of the dozer passing through the swing radius.

- The excavator operator was not required to sound a warning horn (or electronic silent horn) to notify the dozer operator of an intention to lift the bucket: The mine procedure for dozers working in the swing radius did not require the excavator operator to sound the horn to give warning of an intention to lift the bucket. Sounding the excavator horn was required only for pre-start and first start up when lifting the bucket and was specified in the excavator start-up procedure. The excavator operator did not sound the excavator horn prior to lifting the bucket to warn the dozer driver. The electronic silent horn system is used for the excavator operator to communicate with trucks located in the loading area. The electronic silent horn is not used at the mine as an excavator to dozer communication system.

- Hydraulic isolation of the excavator was not required, as part of the mine’s procedure, when the excavator passed through the swing radius. There was no visual means to confirm poscom or isolation status of the excavator by the dozer operator. Hydraulic isolation of the excavator can easily be achieved by using the pilot control shut-off lever located beside the excavator operator’s seat.

- The mine site has installed coloured warning lights on mobile mining equipment (dozers and small excavators). The coloured light system provides confirmation of pos-com to nearby mobile plant operators. The light system is not used to indicate isolation status. The coloured light system was not available on the larger excavators at the mine.

For more information view the investigation information release.

Read more Mining Safety News