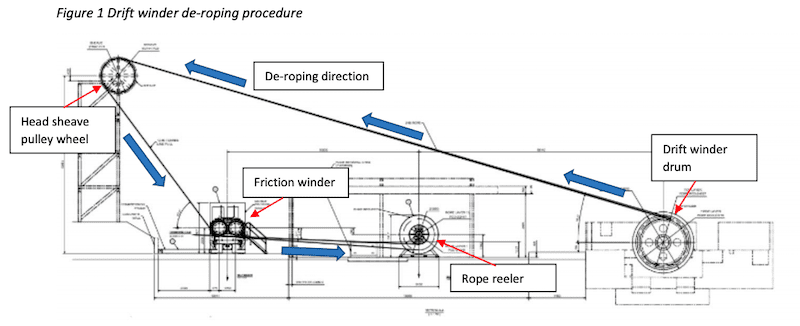

The NSW Resources Regulator has released investment information regarding a dangerous incident at Appin Colliery, Appin on 6 October 2020. According to the report, as part of an equipment upgrade project, during the removal of the winder rope from the Appin East drift winder, the head sheave pulley wheel, weighing several tonnes, dislodged from its support frame and fell approximately 13 metres to the ground below. At the time, a contract worker was positioned on the ground level, within a taped off, restricted access area directly below the pulley wheel. The worker had to move in order to avoid being struck by the falling object. No injuries resulted from the incident.

The NSW Resources Regulator’s initial inquiries have indicated that:

- The friction winder’s maximum rope pull force was set above the maximum safe working load limit of the head sheave pulley assembly.

- During the rope removal, significant forces were exerted onto the head sheave pulley wheel assembly which likely damaged the assembly components, resulting in the pulley wheel dislodging from its support frame and falling to the ground.

- Implemented communication protocols had not appropriately considered the work environment, such as loud background machinery noise.

- Restricted access areas were not clearly defined within procedures or adequately implemented through clear instruction and supervision.

- During the rope removal, a worker was positioned below the head sheave pulley wheel, within a restricted access area, under the assumption that approval had been given to do so.

Mine operators and contractors are reminded of their duty to identify hazards and manage risks to health and safety in accordance with the provisions of the Work Health and Safety Act 2011 and Work Health and Safety (Mines and Petroleum Sites) Act 2013 and regulations.

Report into the serious injury of a worker at Appin North Mine

Worker’s arm caught in tail pulley

Mine operators should:

- Ensure change management procedures are developed, implemented and routinely followed to appropriately consider the health and safety risks associated with modifying existing work processes.

- Monitor and review contractors’ procedures and supervise work practices to ensure implemented safety controls are consistent with the mines safety management system.

- Review drift winder rope removal procedures and risk assessments to ensure that the safe working load limits of the involved plant and equipment are appropriately considered.

Contractors should:

- Ensure drift winder rope removal procedures and risk assessments incorporate appropriate engineering controls to prevent the safe working load limits of the involved plant and equipment from being exceeded.

- Provide adequate instruction and supervision to workers to ensure that, when task procedures have changed from those originally planned, adequate new risk control measures are put in place.

- Review communication protocols to ensure that appropriate consideration is given to the work environment, such as loud background machinery noise.

- Ensure procedures clearly articulate no-go zones and restricted access areas with workers provided clear instruction, training and supervision to ensure they are adhered to.

Workers should:

- never enter identified no-go zones in the potential line-of-fire of falling objects caused by equipment failure while energy is being applied to a pulling system.

Read more Mining Safety News