The Queensland Department of Natural Resources Mines and Energy has issued a mine safety alert regarding a September 2018 incident where a Caterpillar 740B water truck. The alert highlights the need to check service break accumulator function as part of pre-starts and ensure checks of dry-nitrogen pre-charge pressures are conducted at 250-hour services.

The Department stated that when the engine stalled, the pump supplying hydraulic

pressure to the brake system stopped. Despite this, a further two braking options should still have been available to control the water cart:

- the secondary service brake system, normally supplied by brake accumulator pressure in an emergency situation

- the park brake system.

In this instance, the service brake accumulator pressure was too low to provide effective braking. It is thought the operator did not have enough time to activate the park brake switch on the dashboard before losing control of the water cart.

Recommendations for mines

- Machines using accumulators to maintain service braking under hydraulic pump failure or engine stalling, should have accumulator dry nitrogen pre-charge pressures checked by trained personnel every 250 hours.

- In addition to the usual park and service brake tests, service brake accumulator functionality should be checked daily as part of the machine prestart regime.

- Consult with the Original Equipment Manufacturer (OEM) for specific procedures on brake accumulator pre-charge and functionality testing.

- Steering system accumulators operate similarly to brake system accumulators, allowing operation of the steering hydraulic system under hydraulic pump failure or engine stalling. Steering system accumulators should be inspected and tested in accordance with OEM procedures and recommendations.

Link to the Department’s Alert dated 7 January 2019

In other news, today a former CFMEU Official has taken a swipe at the Queensland mines department over the handling of mine safety alert information and practices around a miner in an irrespirable atmosphere last year.

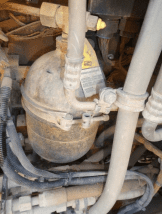

Image: For illustrative purposes only